Laser engraving objects and crafts have pervaded in people’s daily lives. This article aims not to give an elaborate description on this, but to steer you how to make profits from laser engravers. If being utilized in an innovative way, the laser engraver will be a treasure trove for you. Otherwise, it is and will always be a cold machine without feelings, running day after day.

The laser engravers sold by many companies do have various models and applications to cater to different production needs. Some considerate suppliers may also talk to you with a river of words about how well their engravers work or how to operate them rightly. But they seem to forget one thing that how to use the laser engraver is completely depends on “you”! It’s really a pity that there are quite a few purchasers who are convinced by the blueprint drawn by laser engraver salesmen. Apart from selling machines, these salesmen are also good at promising you “pie in the sky”. What a disservice it is!

Here we would like to share some laser engraving experience with you based on our years of industrial accumulation and practice, no matter which supplier you buy your laser engraver from. This sharing, of course, is always built on a good investigation about your purchasing background, purpose, work environment and potential market in advance.

Hard rules do exist in laser engraving industry. These rules can also be golden rules whether you are a novice in laser engraving industry or a senior who plans to upgrade your laser engraver. Let’s now have a look at these 3 rules below.

1.Service

Without any doubt, service is always the NO. 1 rule regarding

buying a laser engraver. You may ask why not the brands or quality of the laser engraver rank first? But here is a question for you - can well-known brands or high quality machines guarantee the service you want before and after buying? Absolutely not. The responsible persistent service and post-sale technological support are the step-stones toward your laser engraving success, regardless a cheaper machine or an expensive one you bought.

2.Size

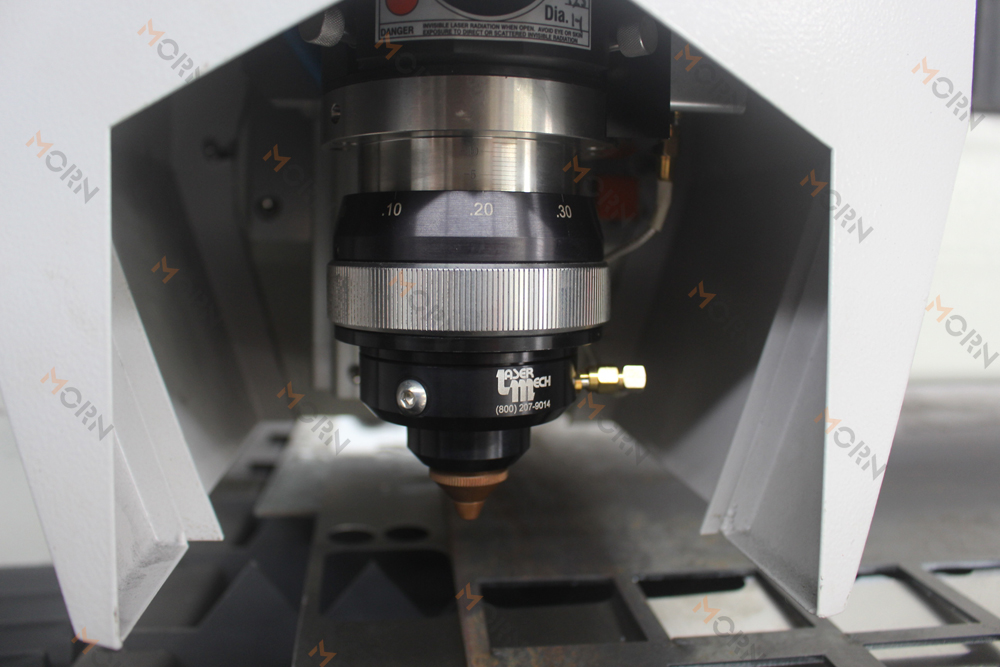

Here 2 types of size matter. The first one is the watt range of a laser engraver. Generally speaking, if you are a novice starting your engraving business without much experience, then a 25-30 watts at least laser engraver may be suitable for you. As an additional device, an air assist is also recommended to help you get deeper and cleaner engraving and cutting results. You can compare the engraving results with and without the air assist. And as for senior people, you could choose proper watt range for your laser engraver.

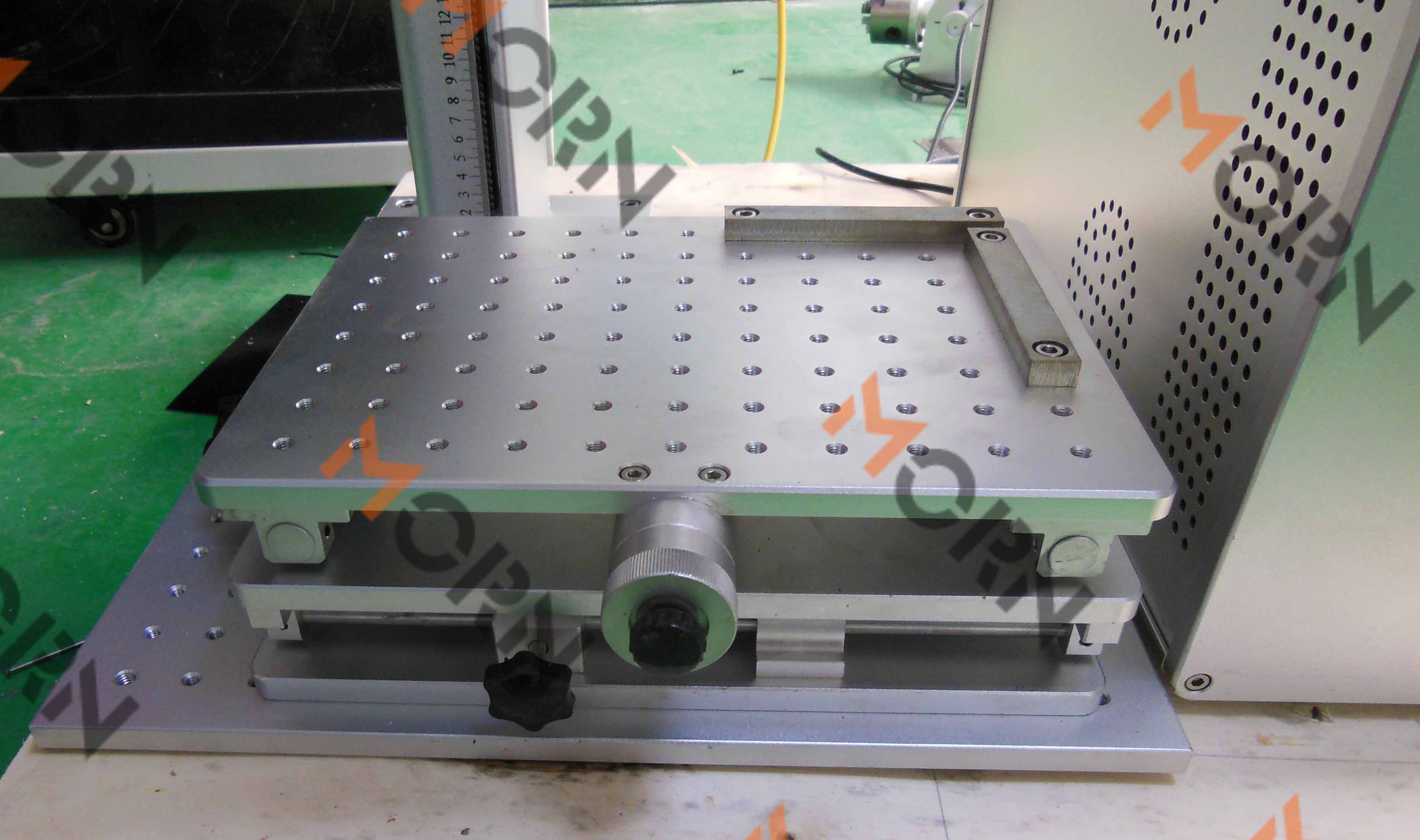

Another size is the size of engraving bed, which is decided by your engraving requirement and budget. Usually the bigger, the better and more expensive. If you just intend to engrave small-size materials, a 12” X 24” engraving bed will be a wise choice to you. And if you also want to engrave some bigger size materials occasionally, a flexible laser engraving machine which can offer a front or rear door capability for larger materials can meet your need.

3.Market

Those fails to achieve success from laser engraving industry are likely to overlook the laser engraving market. Thus an overall and profound research on the market is an essential step on your way of developing laser engraving business. If you have a clear idea about the market, then don’t stay with the status quo. You may work well in the current engraving market and feel satisfied about your profit made from your laser engraving business. But you have to know this is not a business success which comes from continuous innovation and practices, rather than just following the rules of market and being controlled by market demands. To help you improve your laser engraving business, 2 simple standards are sketched as followings.

1) Quality

Both material quality and workmanship quality are of great importance to engraving business. Don’t take your customer’s expectations as your only engraving quality standard. You can try spending extra ten or more minutes to engrave a project and check out what result it will be. And you might surprise your customers in these ten more minutes!

2) On-Time Delivery

In any business including engraving, delivery delay equals to the termination of future cooperation. Don’t run your engraving business by a fluke, even though your engraving results are perfect enough. A well-organized engraving schedule will bring good to you in the long term.

To conclude, we strongly encourage you to develop your laser engraving business via providing decent service, striving for innovation, diving into market and guarantee engraving quality. Stick to these guidelines and you will finally succeed in the laser engraving field.

3.Try to cut with the machine before buying it.

3.Try to cut with the machine before buying it.

4.What materials can I engrave with a laser engraving machine?

4.What materials can I engrave with a laser engraving machine?

6.Will I make money from laser engraving business?

6.Will I make money from laser engraving business?

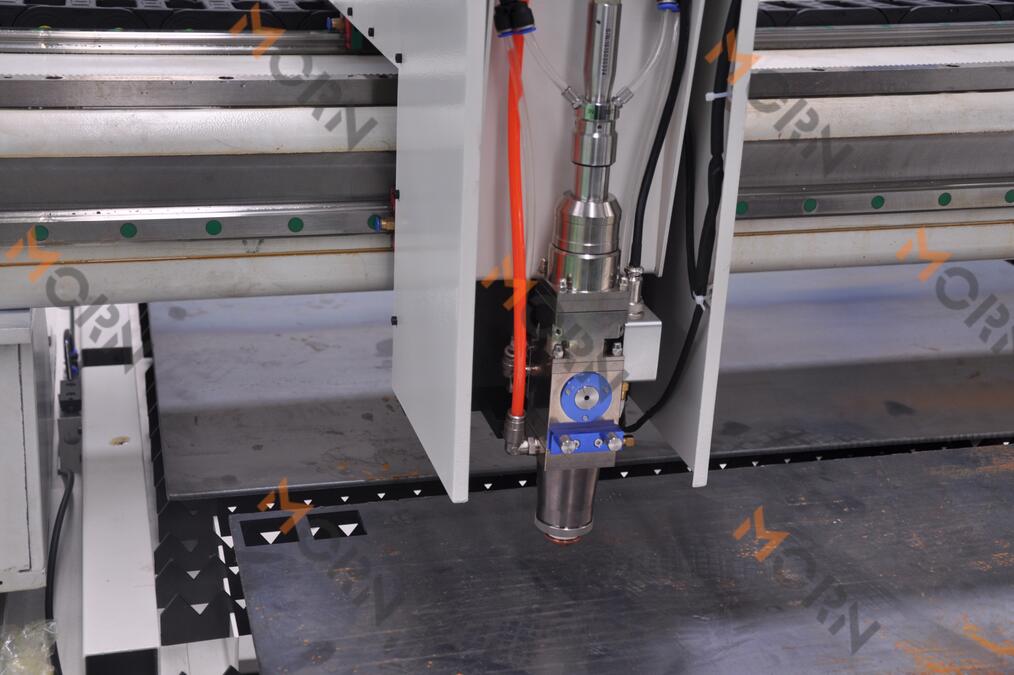

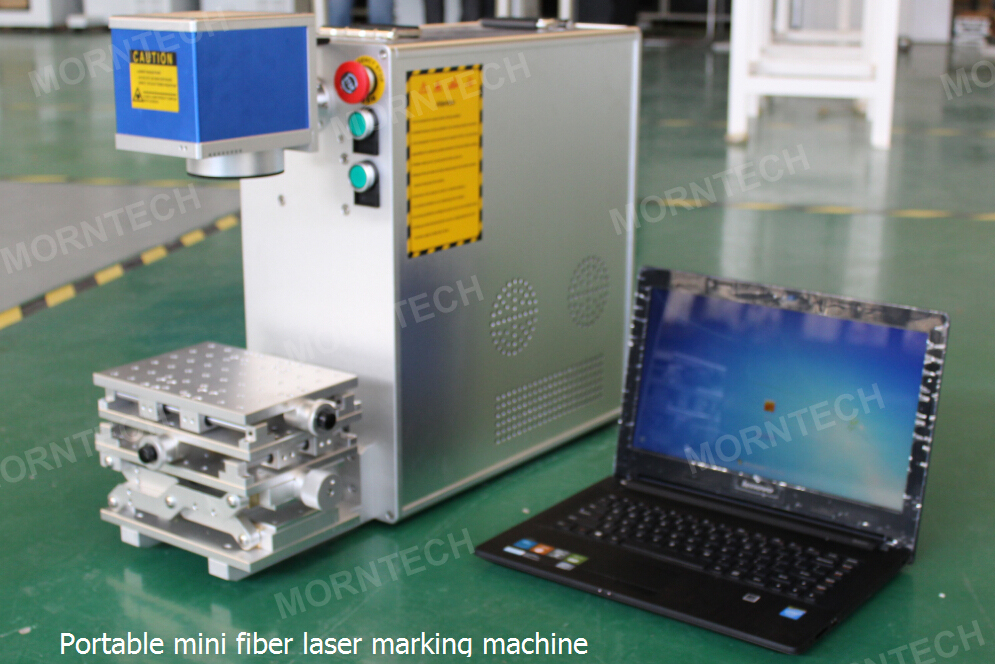

A set of fundamental laser engraving equipment will only cost you as little as no more than $7,000, with which you can buy an affordable laser engraving machine and some raw materials you want engrave. Connecting this engraver to your computer and installing some graphic software package according to your preference. Then the laser engraver will work as a printer that can “print” the patterns you have set in the connected computer.

A set of fundamental laser engraving equipment will only cost you as little as no more than $7,000, with which you can buy an affordable laser engraving machine and some raw materials you want engrave. Connecting this engraver to your computer and installing some graphic software package according to your preference. Then the laser engraver will work as a printer that can “print” the patterns you have set in the connected computer.