Purchasing a fiber laser cutting machine is never a simple thing no matter whether you buy it from local suppliers or overseas suppliers, because it concerns the return your investment will achieve and the benefits your business will receive.

fiber laser cutting machine

Before buying a fiber laser cutting machine, 5 things should be considered to gain the maximum vale from your investment.

Why Choose Fiber Laser Cutting Machine?

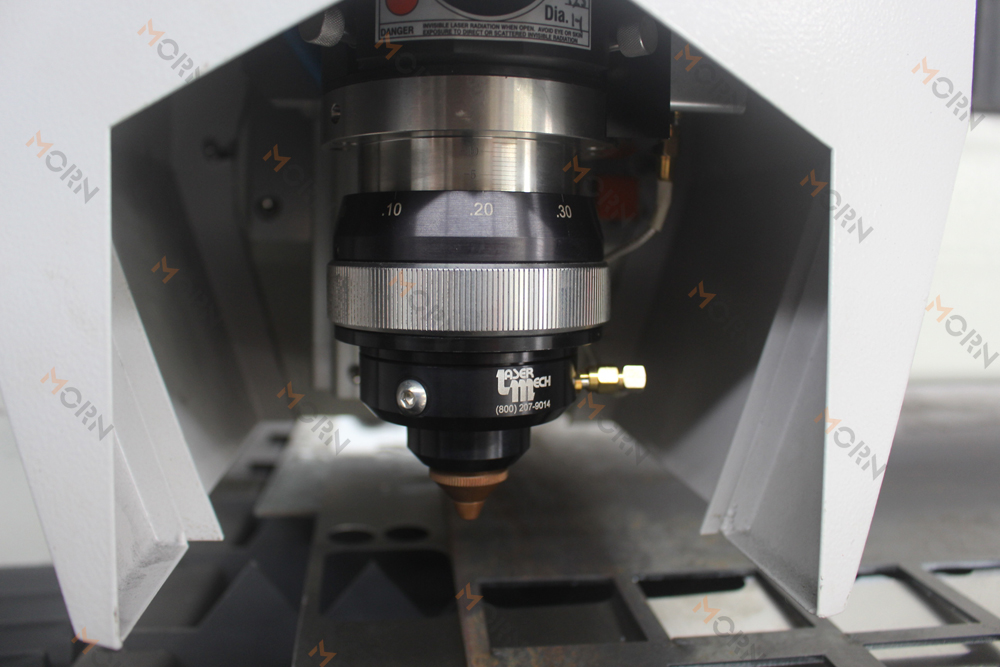

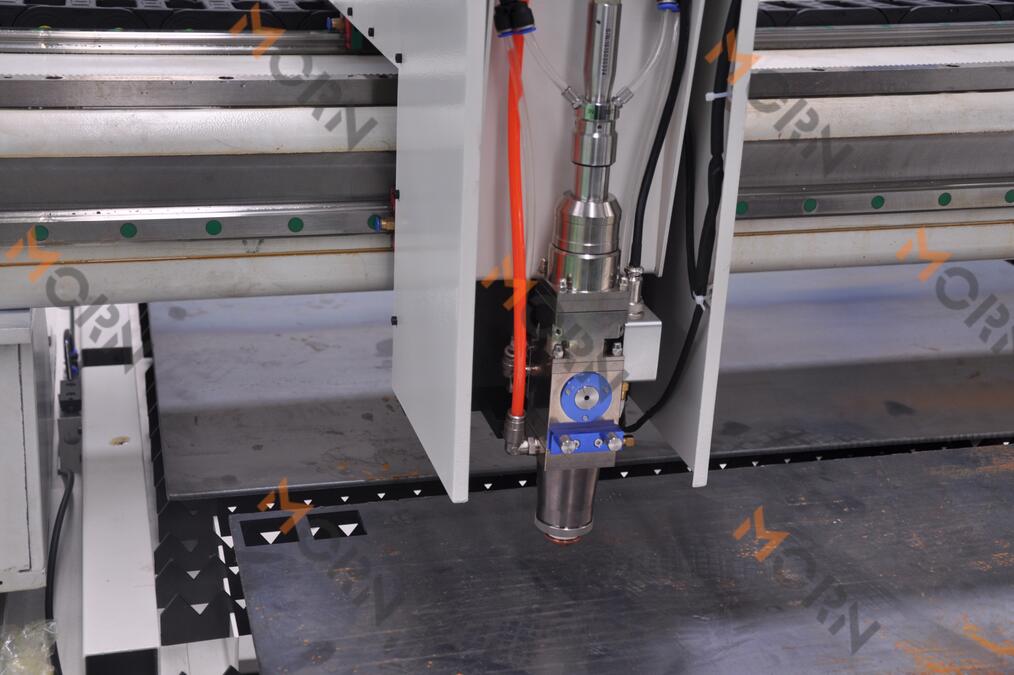

Fiber laser cutting machine is now increasingly used in metal processing industries. It has highly powerful fiber laser beam that works on sheet metals with precise and efficient cutting performance. The laser head won’t directly touch the surface of materials so that the cutting effect is completely protected. The auxiliary cutting gas can be chosen from oxygen and nitrogen, depending on what metal types you plan to work with. The residues produced in the cutting process could be blown out by auxiliary cutting gas and collect in the waste collection box below the lathe. Hence the total cutting process is clean and environmentally friendly.

When it comes to metal cutting, YAG laser, plasma laser, CO2 laser and fiber laser all are able to cut metals, but with different cutting thickness, speed, precision and efficiency. The main differences lie in that YAG cut metals with higher electrical consumption, low efficiency and high maintenance cost; plasma can be used to cut sheet and thick metals, and it especially works better on thick materials; CO2 laser cutting machine is also suitable for thick metals cutting with higher cost and not very high precision; fiber laser cutter is currently the leading laser cutting solution by virtue of its superior cutting accuracy (0.02mm/min), lower energy consumption, higher productivity and little maintenance.

How to Select a Fiber Laser Cutting Machine for Metals?

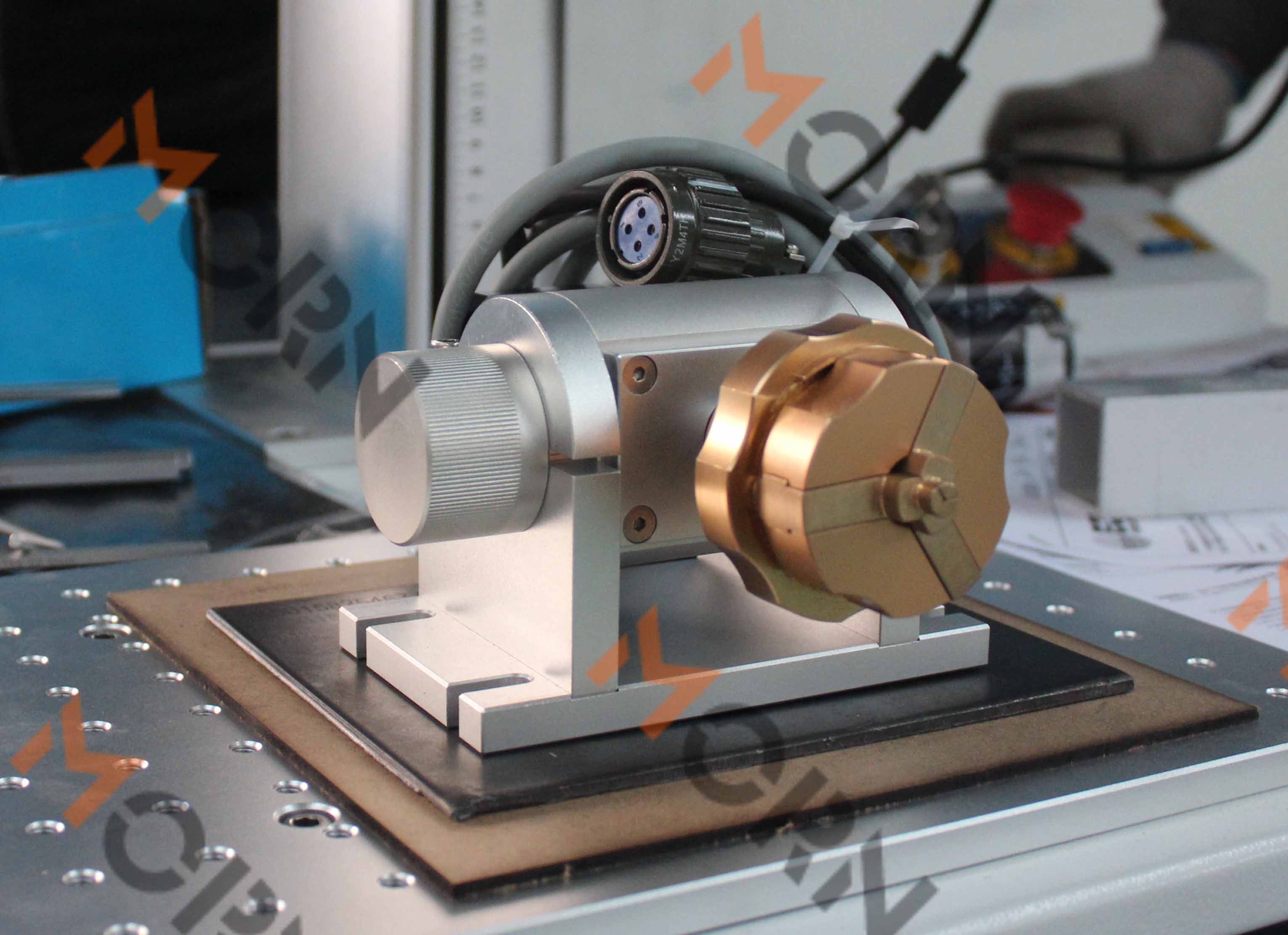

You should decide whether your materials involve steel tubes, for which we could configure an extra fiber laser tube cutting device for the laser equipment. Also, if your materials contain highly reflective metals, such as silver, aluminum, red copper, etc, we would recommend you nLIGHT laser source which is perfectly suitable for reflective materials processing.

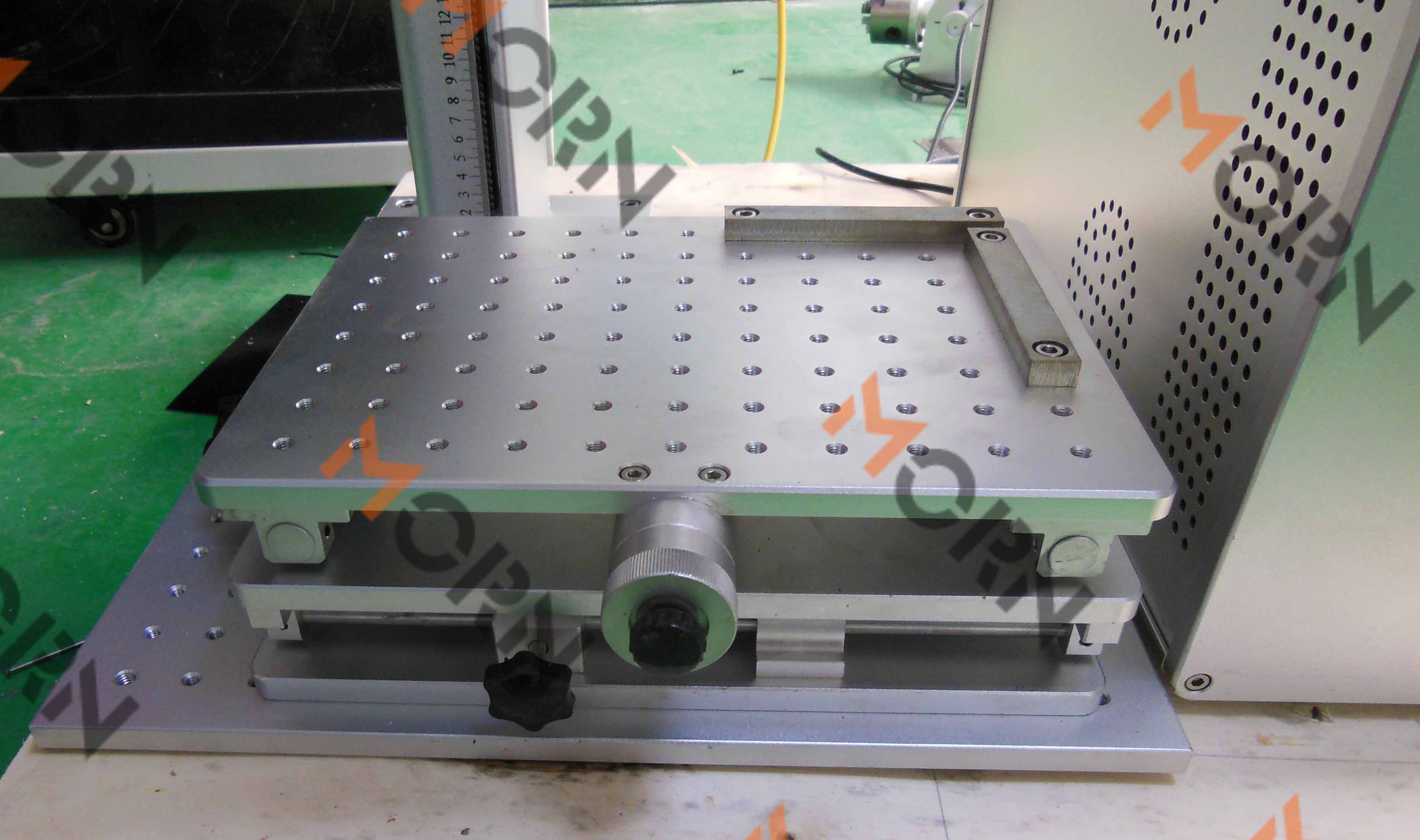

Material size is also key to the fiber laser cutting machine selection. It’s decided by the size of both the products you manufacture and workshop space. You should take a careful measurement on them and then decide the size of work table or the lathe of fiber laser cutter.

In order to achieve perfect cutting effect and work efficiency, the thickness of material has to be matched with the wattage of fiber laser cutting machine. Also your intended productivity per day will help you choose the most productive wattage which has direct influence on cutting speed. Still, please note that different metals that have the same thickness require different wattage.

How to Choose a Reliable Fiber Laser Cutting Machine Manufacturer?

Choosing a fiber laser cutting machine manufacturer is sometimes like a bet with uncertainty and risk, especially in international transactions. Do not worry, as a professional laser machine manufacturer, we could assure you by the following 4 advantageous respects.

Jinan MORN Technology Co., Ltd. (MORN GROUP) is a leading laser machine manufacturers and exporter in China. We are specialized in fiber laser cutting machine and fiber laser marking machine with 10 years experience.

We provide a range of product models and configurations to meet diverse work needs and budgets. Branded with MORN LASER, our top-rated products are fiber laser series and CO2 lasers featured with superior quality, precise work performance and high speed.

We have provided user-centered laser product solutions for customers from more than 130 countries, where they run good business with our fiber laser equipment and give us more support to serve local customers and prospects.

We have professional manufacturing and service flow, with production, R&D, technical sales, quality control and marketing sectors set up for offering exquisite laser solutions. Now we have 136 senior technicians, including 16 senior engineers, more than 50-person sales team and over 30 professional pre-sales & after-sales staff.

High grade raw materials, standard production lines, skilled workers and strict quality control all ensure the credible quality of our

fiber laser metal cutting machines that have got CE and FDA certificates.

We provide quality fiber laser cutting machines with full service and technical support. Customized training service can help users operate the fiber laser machine quickly and safely. Overseas installation and maintenance service is also available for each customer. If you come across any machine fault, our 24-hour online after sales technicians are always here to offer instant solutions. Plus, we could recommend you our long-term cooperative customers in your local area, from which you could contact them to know better about our brand and our fiber laser cutters.

Free Sample TestBesides, since the day our company was established, we have been doing the global layout, and now we have applied for brand and patent protection in 55 countries. We have set up branches and agents in Europe, the United States and Southeast Asia.

If you are not sure whether our fiber laser cutting machine works well with your materials, we could try to cut them with our fiber lasers based on your requirement. Then we would send you the pictures and work videos of the whole process to you without charge.

Most Popular FAQ

Do you manufacture your own Fiber Lasers?

Yes, we manufacture our own Fiber Lasers, from low power pulsed Lasers to high power lasers to help you find the most suitable and economical solution; from raw materials to the final finished laser product, we all produce them in our factory. In addition, our factory is equipped with advanced manufacturing facilities that guarantee a high standard production lines. Welcome to visit our factory and test our fiber laser cutters on the spot.

Fiber Laser Metal Cutting Machine Reviews

“Subcontractors are most likely to adopt the new fiber technology, either those that specialize in cutting thin metal such as for point-of-sale sheet metal work and white goods, or firms using a fiber machine’s strengths to complement CO2 laser machines cutting thicker grades of plate.”

“Current technology is changing and the costs and cutting speeds will change dynamically as manufacturers address issues related to nozzle design, focus lens length, and other pertinent data points. In other words, the operating costs and cutting speeds are not static. Fiber lasers are a somewhat younger technology and the cutting speeds may have a significant upside potential.”

“Some popular laser machine brands can be also notorious in some cases. When selecting a fiber laser cutting machine, users should not only believe what they saw in the supplier’s website or advertising. If possible, try to visit the manufacturer and test the machine in the factory, to ensure your investment is worthy.”